Project Estimating

Prior to generating an estimate, our sales and engineering teams conduct a comprehensive assessment of the project requirements. We collect all relevant technical data to ensure the proposed forming system is optimized for structural performance, site conditions, and cost-efficiency.

Along with the estimate, we provide a preliminary forming layout to facilitate technical review and ensure alignment with the project’s construction methodology.

Shipping & Logistics

We utilize a combination of in-house logistics and trusted third-party carriers to ensure flexible, reliable delivery of our formwork systems across North America. Our logistics team carefully coordinates shipments to align with project timelines and site readiness, reducing downtime and ensuring that materials arrive exactly when needed. Whether it's a full truckload or staged deliveries for complex phased projects, we are equipped to manage transportation efficiently and cost-effectively—no matter the location or project scale.

DESIGN & ENGINEERING

Our in-house engineering team plays a critical role in delivering safe, efficient, and cost-effective formwork solutions tailored to each project’s structural and logistical demands. Using the latest design software and engineering standards, we develop detailed formwork layouts, load calculations, and assembly drawings that ensure compliance with all relevant codes and site conditions.

To support seamless execution on site, we coordinate closely with project teams and arrange site inspections at key stages. These inspections help verify that the forming system is properly installed and ready for concrete placement—minimizing delays and ensuring structural integrity. Our goal is to keep your construction schedule on track while maintaining the highest standards of safety and quality.

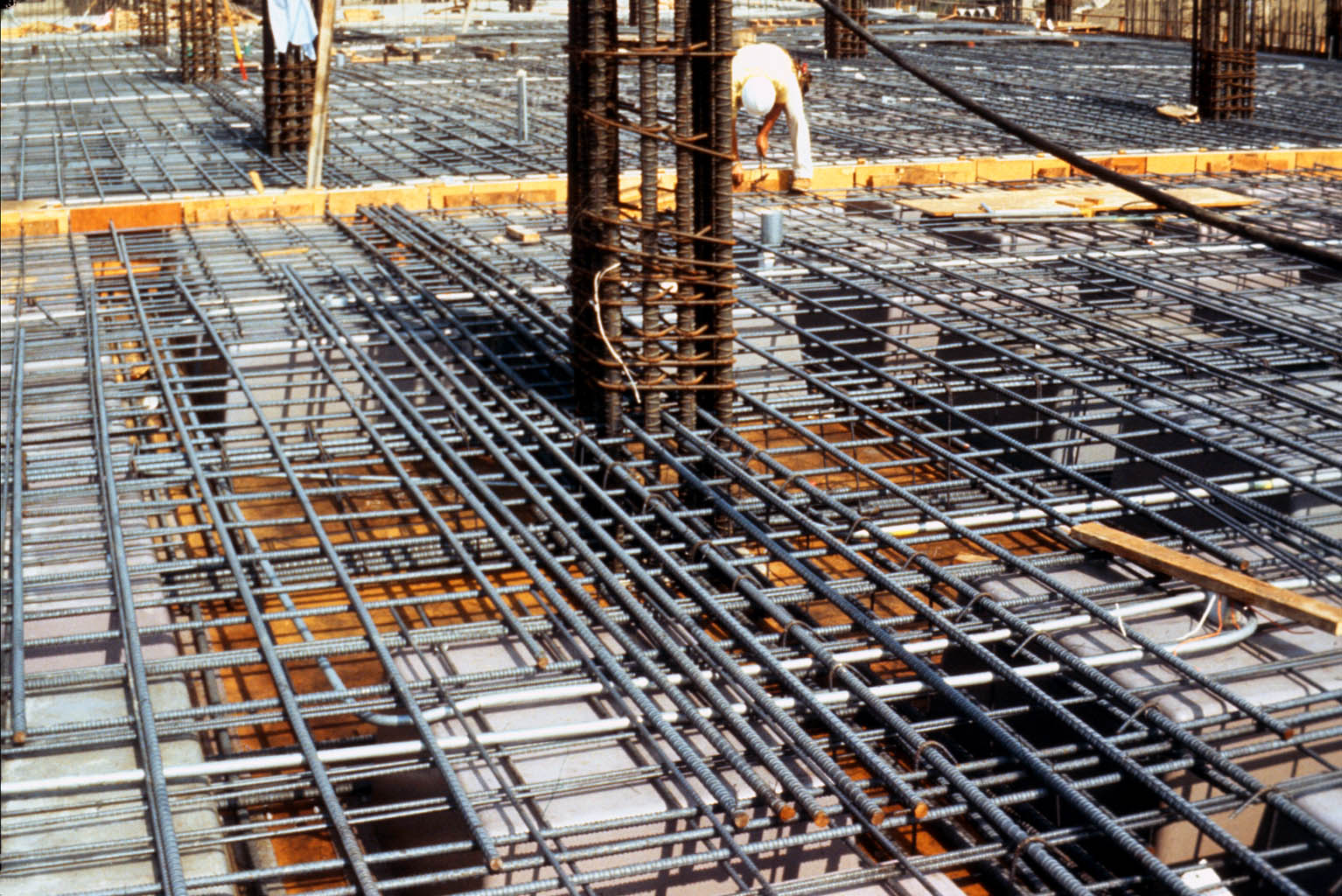

Rebar Services

We offer a full range of in-house rebar solutions, ensuring a seamless process from start to finish:

1. Comprehensive Service: From design and estimation to fabrication and installation.

2. Custom Shop Drawings: Precise rebar detailing tailored to your project’s structural needs.

3. Bending Schedules: Accurate schedules to ensure proper reinforcement placement and compliance with engineering specifications.

4. Close Coordination: Constant communication with engineers and Project Managers to resolve potential conflicts early and optimize project workflows.

5. Quality Control: Full in-house management of rebar detailing, cutting, and bending to maintain strict quality standards.

6. Timely Delivery: Just-in-time delivery for efficient installation and to support concrete placement schedules.

Shoring

Engineered for exceptional value and versatility, this formwork system is designed to perform reliably even in the most demanding site conditions. With the capability to reach heights of up to 64 feet, it sets the industry benchmark for performance, flexibility, and cost-efficiency—making it the gold standard in modern concrete formwork.

formply

High-performance decking solutions are essential for fast, repeatable concrete work in commercial construction. Engineered for speed and efficiency, these systems enable rapid installation and clean removal, reducing cycle times and keeping crews productive. Designed for consistency, they ensure precise slab quality across multi-story builds, making them ideal for large-scale commercial projects where uniformity is critical. With heavy-duty components built to withstand demanding loads, these decking solutions streamline the pour process, minimize labor needs, and maximize output.